Product Overview:The XSG series rotary flash drying machine is a new type of drying equipment developed by our factory on the basis of introducing and absorbing foreign technology. The technology of this machine is well-designed, compact in structure, widely applicable, with large production capacity, good product quality, high efficiency, and energy-saving.

Overview:The XSG series rotary flash drying machine is based on the introduction and absorption of foreign technology by our factory

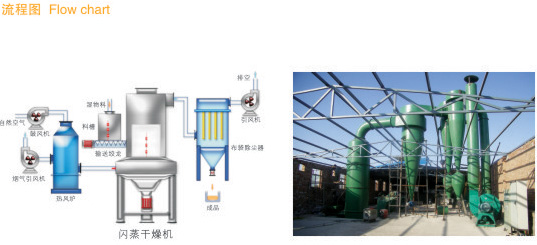

Category:Flash drying machine

Detailed explanation:

Overview:

The XSG series rotary flash drying machine is a new type of drying equipment developed by our factory on the basis of introducing and absorbing foreign technology. The technology of this machine is well-designed, compact in structure, widely applicable, with large production capacity, good product quality, high efficiency, and energy-saving. It can be dried, crushed, and screened in one device at a time, eliminating environmental pollution, and the overall performance of the machine reaches the technical level.

Principle:

Hot air enters the mixing and crushing drying chamber from the bottom of the dryer at an appropriate spraying speed through the inlet pipe, exerting strong shearing, blowing, and rotating effects on the material. As a result, the material is subjected to centrifugation, shearing, collision, and friction, and is divided into particles, enhancing mass and heat transfer. At the bottom of the dryer, larger and wetter particle clusters are mechanically crushed under the action of the agitator, while particles with lower moisture content and smaller particle size are carried up by the rotating airflow and further dried during the upward process. Due to the rotational flow between gas and solid phases, the inertia of the solid phase is greater than that of the gas phase, and the relative velocity between the solid and gas phases is higher, which enhances the mass and heat transfer between the two phases. Therefore, the production intensity of this machine is high.

Features:

Multiple feeding devices are available for selection, ensuring continuous and stable feeding without any bridging during the process

A special cooling device is installed at the bottom of the dryer to prevent the material from deteriorating in the high-temperature zone at the bottom

Special air pressure sealing devices and bearing cooling devices effectively extend the service life of the transmission part

The special air distribution device reduces equipment resistance and effectively provides the processing air volume of the dryer

The drying room is equipped with a grading ring and a swirl plate, and the material fineness and final moisture content can be adjusted. (For example, the final water content of calcium carbonate can be adjusted to ≤ 0.1%)

Compared to other drying methods, it can effectively increase the specific gravity of materials

The drying chamber has a high circumferential gas velocity and short material retention time, effectively preventing material adhesion and thermal sensitive material deterioration, achieving fast, small equipment, and large-scale production.

Applicable materials:

● Inorganic materials: Boric acid, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, antimony trioxide, various metal hydroxides, various heavy metal salts, synthetic cryolite, etc

● Organic compounds: atrazine (pesticide insecticide), lauric acid, benzoic acid, benzoic acid, fungicide, sodium oxalate, cellulose acetate, etc

● Ceramics: kaolin, silica, clay

● Dyes: anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various intermediate azo dyes

● Food category: soy protein, gelatinous starch, distiller's grains, wheat sugar, and wheat starch.

Technical parameter table

Model | Host internal management(mm) | Processing air volume(m3/h) | Evaporative water volume(kg/h) | Installed capacity(KW) | Height(m) | Occupy the plane(m2) |

XSG-4 | 400 | 1150-2300 | 58-73 | 21.4 | 4.6 | 27 |

XSG-6 | 600 | 2500-5100 | 130-163 | 34.2 | 5.5 | 39 |

XSG-8 | 800 | 4500-9000 | 238-297 | 63.5 | 6.0 | 40 |

XSG-10 | 1000 | 7000-13500 | 345-430 | 68 | 6.5 | 55 |

XSG-12 | 1200 | 10000-20000 | 515-645 | 94 | 6.8 | 62 |

XSG-14 | 1400 | 16600-28000 | 730-910 | 130 | 7.0 | 89 |

XSG-16 | 1600 | 18000-38100 | 962-1203 | 160 | 7.2 | 160 |

Note: 1. The evaporation of water is calculated based on the inlet temperature of 200 ℃ and the outlet temperature of 80 ℃. 2. The installed capacity is the basic data and can be changed according to the material performance. 3. The land area is arranged according to the actual situation, and the data in the table is for reference only.

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23