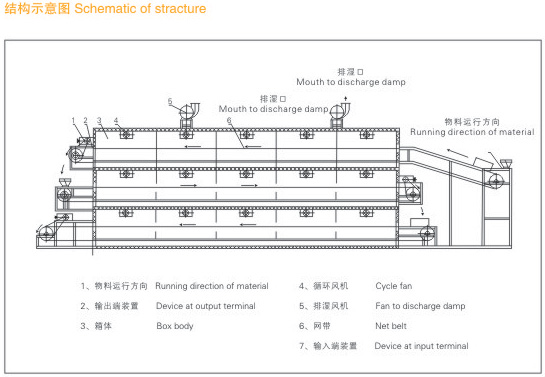

Product Overview:The DW series multi-layer belt dryer is a continuous drying equipment used in batch production, used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for dehydrated vegetables, catalysts, traditional Chinese medicine slices, and other materials with high moisture content and temperature not allowed to be high; This series of dryers has the advantages of fast drying speed, high evaporation intensity, and good product quality. For dehydrated cake like paste like materials, they need to be granulated or made into strips before drying.

Description: The DW series multi-layer belt dryer is a continuous drying equipment used in batch production

Category: Belt dryer

Detailed explanation:

Product Introduction:

The DW series multi-layer belt dryer is a continuous drying equipment used in batch production, used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for dehydrated vegetables, catalysts, traditional Chinese medicine slices, and other materials with high moisture content and temperature not allowed to be high; This series of dryers has the advantages of fast drying speed, high evaporation intensity, and good product quality. For dehydrated cake like paste like materials, they need to be granulated or made into strips before drying.

Overview:

The DW series multi-layer belt dryer is suitable for large-scale production of difficult to dry materials with low drying rates. The equipment has a compact structure, small footprint, simple operation, convenient maintenance, and stable operation. It can be designed into different forms of hot air circulation drying based on the drying characteristics of materials, which is an extension and improvement of hot air circulation ovens and widely used in fields such as metallurgical additives, chemical industry, food, packaging, etc. With the advancement of enterprise technology and the improvement of product technology content, multi-layer belt dryers have the ability to meet the needs of large-scale production, diversification, centralized control, and continuous production. It has the advantages of energy conservation and easy management.

Technical parameter table:

Model | DW3-1.2-8 | DW3-1.2-10 | DW3-1.6-8 | DW3-1.6-10 | DW3-2-8 | DW3-2-10 | ||

Number of units | 4X3 | 5X3 | 4X3 | 5X3 | 4X3 | 5X3 | ||

Drying section length (m) | 24 | 30 | 24 | 30 | 24 | 30 | ||

Paving thickness (mm) | 10-80 | |||||||

Operating temperature ℃ | 50~140 | |||||||

Steam pressure Mpa | 0.2~0.8 | |||||||

Steam consumption (kg/h) | 360-600 | 420-720 | 450-840 | 480-960 | 480-960 | 630-1350 | ||

Heat exchange area (m2) | 816 | 1020 | 1056 | 1320 | 1344 | 1680 | ||

Drying strength (kgH2O/h) | 150-450 | 220-550 | 240-600 | 280-750 | 280-750 | 350-900 | ||

Total internal power (KW) | 30.8 | 37.4 | 42 | 51 | 56 | 68 | ||

Total power of external units (KW) | 35.3 | 41.9 | 46.5 | 55.5 | 60.5 | 72.5 | ||

External dimensions (m) | 9.77X2.2X4.5 | 11.77X2.2X4.5 | 9.77X2.6X4.5 | 11.77X2.6X4.7 | 9.77X3.06X4.9 | 11.77X3.06X4.9 | ||

Total weight (kg) | 4800X3 | 5780X3 | 5400X3 | 6550X3 | 6350X3 | 7800X3 | ||

Note: For drying temperatures between 250~350 ℃, our company can make special designs based on the actual materials. | ||||||||

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23