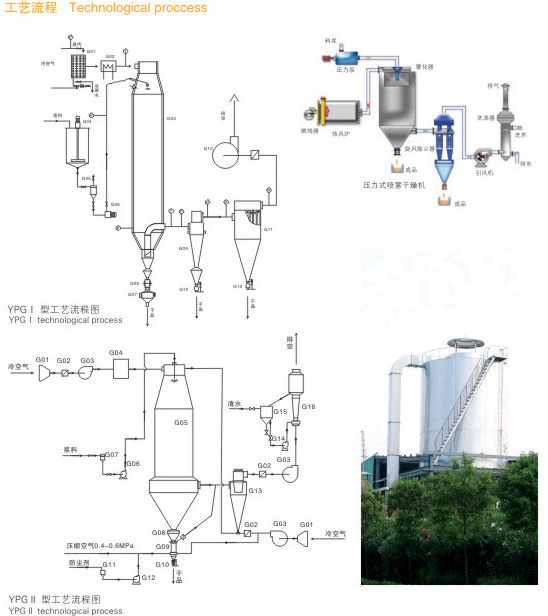

Brief description: the pressure type spray drying granulator uses the pressure type atomizer to atomize the solution or slurry materials into fine droplets with the help of the pressure of the diaphragm pump

Category: spray dryer

Detailed explanation:

Overview:

The pressure type spray drying granulator is a kind of equipment that uses the pressure type atomizer to atomize the solution or slurry like materials into tiny liquid drops with the help of the pressure of the diaphragm pump, so that the surface area can be significantly increased, and it can be quickly dried (tens of seconds to tens of seconds) through full heat exchange with the hot air, so as to obtain powder or fine particle products.

Features:

● Fast drying speed, especially suitable for heat sensitive materials

● The obtained product is spherical particles with uniform particle size, good fluidity and solubility, high purity, and good quality

● It can be used in a wide range, including hot air drying, granulation, cooling granulation, spray crystallization, spray reaction, etc

● It can be equipped with a fine powder return and wet agglomeration system to meet the user's requirements for material particle size

● Simple and stable operation, convenient control, and easy to achieve automated operation. The product particle size, bulk density, and water powder can be adjusted within a certain range

Application:

Liquids with corresponding fluidity are suitable for food, medicine, chemical, dyeing, ceramics, biochemistry, pesticides, plastics, etc.

Technical parameter table:

| Model | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Water evaporation capacity (Kg/h) | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| External dimensions (Φ×H)mm | 1600×8900 | 2000×11500 | 2400×13500 | 2800×14800 | 3200×15400 | 3800×18800 | 4600×22500 |

| High pressure pump pressure (Mpa) | 2-10 | ||||||

| 功率KW | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| Air inlet temperature ℃ | 300-350 | ||||||

| Product moisture content % | ﹤5(Up to 0.5) | ||||||

| Material recovery % | ﹥97 | ||||||

| Electric heating KW | 75 | 120 | 150 | When the temperature is below 200 degrees, the specific calculation will be based on the actual situation | |||

| Electric steam Mpa+KW | 0.5+54 | 0.6+90 | 0.6+108 | ||||

| Hot air stove Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail.

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23