Overview:The production process of chicken essence is as follows: grains (wheat, corn, soybeans) - semi-finished monosodium glutamate

Overview:The production process of chicken essence is as follows: grains (wheat, corn, soybeans) - semi-finished monosodium glutamate

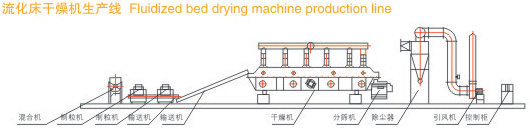

Category:Fluidized bed dryer

Detailed explanation:

Overview:

The production process of chicken essence includes: grains (wheat, corn, soybeans) - monosodium glutamate semi-finished products (sodium glutamate) mixed with a small amount of chicken powder and other auxiliary materials - granulation - drying - sieving - packaging - inspection - finished products - storage. To obtain chicken essence products with excellent color, aroma, and shape; The selection of excipients is crucial. The quality of semi-finished monosodium glutamate (sodium glutamate) and oil tire plays a decisive role in the production of chicken essence. In terms of drying, as the main component of chicken essence is derived from sodium glutamate, which becomes the focus when the temperature exceeds 120 ℃, sodium glutamate is harmful to the human body after consumption. Therefore, when drying chicken essence, the temperature in the drying room needs to be controlled between 95 ℃ and 115 ℃ in order to fully realize the nutritional value of chicken essence.

Our company has been dedicated to the research and development of production line equipment for chicken essence and chicken powder for many years. To date, we have developed multiple sets of production line equipment for chicken essence and chicken powder with different processes, all of which are made of stainless steel to meet the needs of users for QS certification. There are already several top ten chicken essence manufacturers in China and manufacturers with larger sales in East China using our company's chicken essence and chicken powder production line equipment.

Drying process description:

Our company has made significant improvements to the conventional vibrating fluidized bed dryer to meet the process requirements of chicken essence drying production. It has been applied in multiple chicken essence manufacturers and has received high praise from users.

Chicken essence has a certain viscosity and is prone to sticking to the bed surface of the dryer, causing drying to be impossible. Our company has taken various measures to address this issue. After the squeezing and granulation of chicken essence, the surface moisture is relatively high. Our company's fluidized bed adopts low-temperature and high air volume pre drying, which quickly reduces the surface moisture of chicken essence and also reduces the surface viscosity. The second stage of the fluidized bed adopts medium temperature and high air flow drying to further reduce the surface moisture of chicken essence. The third stage of the fluidized bed adopts medium temperature conventional air flow drying to allow sufficient residence time of chicken essence in the fluidized bed for effective drying. The fourth section of the fluidized bed adopts high air flow cooling, which facilitates the direct packaging of chicken essence after screening. In summary, in order to meet the process requirements of chicken essence at different stages, there are corresponding design specifications for the bed opening rate, opening direction, and fan selection.

To improve the fluidization effect and operational reliability of the fluidized bed during chicken essence drying, our company has increased the volume of the boiling chamber in the fluidized bed produced, and the main unit adopts a frame structure.

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23