Product Overview:Wedge shaped hollow blades are densely arranged on the hollow shaft, and the hot medium flows through the blades through the hollow shaft. The heat transfer area per unit effective volume is large, and the temperature of the thermal medium ranges from -40 ℃ to 320 ℃. It can be steam or liquid, such as hot water, thermal oil, etc.

Overview:Wedge shaped hollow blades are densely arranged on the hollow shaft, and the hot medium flows through the blades through the hollow shaft. The heat transfer area per unit effective volume is large, and the temperature of the thermal medium ranges from -40 ℃ to 320 ℃. It can be steam or liquid, such as hot water, thermal oil, etc.

Category: Paddle dryer

Detailed explanation:

Overview:

Wedge shaped hollow blades are densely arranged on the hollow shaft, and the hot medium flows through the blades through the hollow shaft. The heat transfer area per unit effective volume is large, and the temperature of the thermal medium ranges from -40 ℃ to 320 ℃. It can be steam or liquid, such as hot water, thermal oil, etc. Indirect conduction heating does not carry air away heat, and the heat is used to heat the material. The heat loss is only the heat dissipation to the environment through the insulation layer of the device. The heat transfer surface of the wedge-shaped blade has self-cleaning function. The relative motion between material particles and the wedge surface generates a cleaning effect, which can wash away the attached materials on the wedge surface and maintain a clean heat transfer surface during operation. The shell of the paddle dryer is W-shaped, and two to four hollow mixing shafts are generally arranged inside the shell. The shell has a sealed end cover and an upper cover to prevent the leakage of material dust and the collection of solvent vapors. Set a stopper at the discharge port to ensure the height of the material level, so that the heat transfer surface is covered by the material and fully utilized. The hot medium flows through the shell jacket and the hollow stirring shaft through the rotating joint. The hollow stirring shaft has different internal structures according to the type of hot medium to ensure good heat transfer effect.

Application:

Paddle dryers have been successfully used in fields such as food, chemical, petrochemical, dye, and industrial sludge. The characteristics of heat transfer, cooling, and stirring of the equipment enable it to complete the following unit operations: calcination (low temperature), cooling, drying (solvent recovery), heating (melting), reaction, and so on. The mixing blade is also a heat transfer surface, which increases the heat transfer area per unit effective volume and shortens the processing time. The wedge-shaped blade heat transfer surface also has self-cleaning function. The compression expansion mixing function ensures even mixing of materials. The material moves in a piston flow along the axial direction, and within the axial range, the temperature, humidity, and mixing gradient of the material are very small.

● Using thermal oil as the thermal medium, the blade dryer can complete low-temperature calcination work. For example, calcium sulfate dihydrate (Ca2SO4 · 2H2O) is calcined and converted into calcium sulfate hemihydrate (Ca2SO4 · 1/2H2O). Sodium bicarbonate (NaHCO3) is transformed into pure alkali (Na2CO3) through calcination.

● Cooling media such as water and cooling salt water can be introduced for cooling. For example, the blade type alkali cooler used in the soda ash industry replaces the old air cooled alkali cooler, saving energy and exhaust gas treatment equipment, reducing operating costs, and can also be used for cooling titanium, nickel iron alloy powder, and various powder like materials. Materials can be cooled from 1000 ℃ to less than 40 ℃ in a single machine.

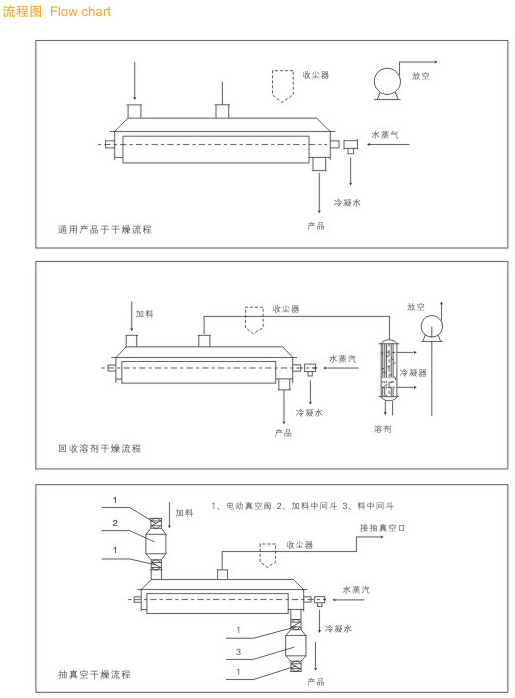

● Drying, the main function of the equipment, does not use hot air, making solvent recovery, energy consumption, and environmental control in an ideal state that is easy to handle. It is particularly suitable for solvents that need to be recycled, as well as for flammable, easily oxidizable, and heat sensitive materials. It has been widely used in the fine chemical, petrochemical, and dye industries.

● The uniformity of temperature, humidity, and mixing degree within the axial range allows the equipment to be used for heating or melting, or for some solid material reactions. It has been successfully used in the compound fertilizer and modified starch industries. Paddle dryers can be used to process food and flour. The large heating area per unit effective volume quickly heats the material to temperature, avoiding prolonged heating that can alter the quality of the material.

Adapt to materials

Petrochemical industry: polyolefin powder, polycarbonate resin, high and low density polyethylene, linear low-density polyethylene, polyacetal particles, nylon 6, nylon 66, nylon 12, acetate fiber, polyphenylene sulfide, propylene based resin, engineering plastics, polyvinyl chloride, polyvinyl alcohol, polystyrene, polypropylene, polyester, polyformaldehyde, styrene acrylonitrile copolymerization, ethylene propylene copolymerization.

Environmental protection industry: PTA sludge, electroplating wastewater sludge, boiler ash, pharmaceutical factory waste, sugar factory waste, monosodium glutamate factory waste, and coal ash.

Feed industry: soy sauce residue, bone based feed, distiller's grains, food scraps, apple pomace, orange peel, soybean meal, chicken bone feed, fish meal, feed additives, biological sludge

Food industry: starch, cocoa beans, corn kernels, salt, modified starch, pharmaceuticals.

Chemical industry: soda ash, nitrogen phosphorus potassium compound fertilizer, kaolin, bentonite, white carbon black, carbon black, phosphogypsum, sodium fluoride oxide, calcium nitrate, magnesium carbonate, aluminum hydroxide, barium sulfate, calcium sulfate, calcium carbonate, dyes, molecular sieves, saponins.

Features:

● The blade dryer has low energy consumption: due to indirect heating, it does not carry a large amount of air to carry away heat. The outer wall of the dryer is also equipped with an insulation layer, which only requires 1.22kg of water vapor to evaporate 1kg of water for slurry materials.

● The blade dryer system has low cost: it has a huge heat transfer surface per unit effective volume, which shortens processing time and reduces equipment size. This greatly reduces the building area and space.

● Wide range of material processing: using different thermal media, it can handle both thermosensitive materials and materials that require high-temperature treatment. Common media include steam, heat transfer oil, hot water, cooling water, etc. It can be operated continuously or intermittently and can be applied in many fields.

● Low environmental pollution: do not use carrying air, and carry very little dust and materials. The solvent evaporation of the material is very small, making it easy to handle. For contaminated materials or operating conditions that require solvent recovery, closed-loop circulation can be used.

● Low operating costs: The device operates normally, with only 1-2 people per day. Low speed stirring and reasonable structure. Low wear and tear, low maintenance costs.

● Stable operation: Due to the special compression expansion stirring effect of the wedge-shaped blade, the material particles are fully in contact with the heat transfer surface. Within the axial range, the temperature, humidity, and mixing gradient of the material are very small, ensuring the stability of the process.

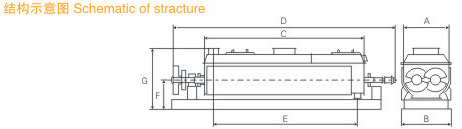

| Characteristic parameter table | ||||||||

| Model | KJG-2.7 | KJG-9 | KJG-13 | KJG-18 | KJG-24 | KJG-29 | KJG-36 | KJG-41 |

| Heat transfer area (m2) | 2.7 | 9 | 13 | 18 | 24 | 29 | 36 | 41 |

| Effective volume (m3) | 0.06 | 0.32 | 0.59 | 1.09 | 1.53 | 1.85 | 2.42 | 2.8 |

| Speed range (r.p.m) | 15-30 | 10-25 | 10-25 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 |

| Power (kw) | 2.2 | 4.0 | 5.5 | 7.5 | 11 | 11 | 15 | 15 |

| Body width (A mm) | 306 | 584 | 762 | 940 | 1118 | 1118 | 1296 | 1296 |

| Total width (B mm) | 736 | 841 | 1066 | 1320 | 1474 | 1474 | 1676 | 1676 |

| Body length (C mm) | 1956 | 2820 | 3048 | 3328 | 3454 | 4114 | 4115 | 4724 |

| Total length (D mm) | 2972 | 4876 | 5486 | 5918 | 6147 | 6808 | 6960 | 7570 |

| Incoming and outgoing distance (E mm) | 1752 | 2540 | 2768 | 3048 | 3150 | 3810 | 3810 | 4420 |

| Center height (F mm) | 380 | 380 | 534 | 610 | 762 | 762 | 915 | 915 |

| Total height (G mm) | 762 | 838 | 1092 | 1270 | 1524 | 1524 | 1778 | 1778 |

| Steam inlet N inches | (2)3/4 | (2)3/4 | (2) 1 | (2) 1 | (2) 1 | (2) 1 | (2) 1 | (2) 1 |

| Outlet O inch | (2)3/4 | (2)3/4 | (2) 1 | (2) 1 | (2) 1 | (2) 1 | (2) 1 | (2) 1 |

| Characteristic parameter table | |||||||||

| Model | KJG-48 | KJG-52 | KJG-62 | KJG-68 | KJG-73 | KJG-81 | KJG-87 | KJG-95 | KJG-110 |

| Heat transfer area (m2) | 48 | 52 | 62 | 68 | 73 | 81 | 87 | 95 | 110 |

| Effective volume (m3) | 3.54 | 3.96 | 4.79 | 5.21 | 5.78 | 6.43 | 7.39 | 8.07 | 9.46 |

| Speed range (r.p.m) | 10-20 | 10-20 | 10-20 | 10-20 | 5-15 | 5-15 | 5-15 | 5-15 | 5-10 |

| Power (kw) | 30 | 30 | 45 | 45 | 55 | 55 | 75 | 75 | 95 |

| Body width (A mm) | 1474 | 1474 | 1651 | 1652 | 1828 | 1828 | 2032 | 2032 | 2210 |

| Total width (B mm) | 1854 | 1854 | 2134 | 2134 | 2286 | 2286 | 2438 | 2438 | 2668 |

| Body length (C mm) | 4724 | 5258 | 5410 | 5842 | 5461 | 6020 | 5537 | 6124 | 6122 |

| Total length (D mm) | 7772 | 8306 | 8865 | 9296 | 9119 | 9678 | 9119 | 9704 | 9880 |

| Incoming and outgoing distance (E mm) | 4420 | 4954 | 4953 | 5384 | 5004 | 5562 | 5080 | 5664 | 5664 |

| Center height (F mm) | 1066 | 1066 | 1220 | 1220 | 1220 | 1220 | 1220 | 1220 | 1220 |

| Total height (G mm) | 2032 | 2032 | 2362 | 2362 | 2464 | 2464 | 2566 | 2566 | 2668 |

| Steam inlet N inches | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)2 | (2)2 | (2)2 |

| 0 inch steam outlet | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)2 | (2)2 | (2)2 |

Note: Some parameters may be adjusted according to different materials during design

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail.

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23