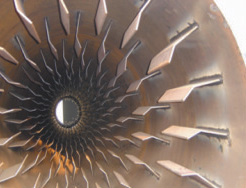

Description: After the wet material is inserted from one end of the dryer, the material is evenly distributed and dispersed in the dryer under the flipping of the inner evenly distributed plate reader

Category: Drum dryer

Detailed explanation:

Overview:

After the wet material is inserted from one end of the dryer, under the flipping of the uniformly distributed plate reader in the inner cylinder, the material is evenly distributed and dispersed in the dryer, and fully contacts with the co current (counter current) hot air, accelerating the drying flow and mass transfer driving force. During the drying process, the material can be adjusted to move to the star shaped discharge valve at the other end of the dryer to discharge the finished product under the action of the inclined plate and hot air flow.

Application:

● In industries such as chemical, mining, and metallurgy, large particles and materials with high density are dried, such as ore, blast furnace slag, coal, metal powder, phosphate fertilizer, and ammonium sulfate.

● Drying of powdered and granular materials with special requirements, such as HP foaming agent, distiller's grains residue, lightweight calcium carbonate, activated clay, magnetic powder, graphite, and pharmaceutical residue.

● Materials that require low-temperature drying and require continuous drying in large quantities.

Features:

● The rotary dryer has a high degree of mechanization and a large production capacity.

● The fluid has low resistance through the cylinder and low functional consumption.

● Strong adaptability to material characteristics.

● Stable operation, low operating costs, and good uniformity of product drying.

Technical parameter table:

Model | Direct heating downstream type | Direct heating counter current type | Composite heating | |||

Material type | mineral | HP foaming agent | Blast furnace slag | Ammonium sulfate | Phosphate fertilizer | Coal |

Processing capacity (kg/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

Initial moisture content % | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

Final moisture content % | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

Average particle size (mm) | 6.5 | 0.05 | 4.7 | 0.5-0.7 | 0.5 | 5 |

Material stacking density (kg/m2) | 770 | 800 | 1890 | 1100 | 1500 | 750 |

Hot air degree (m3/kg) | 39000 | 5400 | 10750 | 9800 | 6500 | 16000 |

Inlet gas temperature ℃ | 600 | 165 | 500 | 180 | 650 | 570 |

Material outlet temperature ℃ | 42 | 100 | 70 | 80 | 75 | |

Heating method | Coal gas | Steam electric heating | Heavy oil | Coal fired hot air stove | Heavy oil | Heavy oil |

Loading coefficient | 6.3 | 7 | 7.5 | 7.8 | 18 | |

Speed (r.p.m) | 4 | 4 | 3.5 | 3 | 4 | 2 |

Inclination (m/m) | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

Number of copied boards | 12 | 24 | 12 | 22 | Outside the inner cylinder 8 | Outside the inner cylinder 6 |

Drier diameter (m) | 2.0 | 1.5 | 2 | 2.3 | Outer cylinder 2 | Outer cylinder 2.4 |

Dryer length (m) | 20 | 12 | 17 | 15 | 10 | 16 |

Drive power (kw) | 22 | 7.5 | 15 | 11 | 11 | 15 |

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail.

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23