Product Overview:Suitable for heating, solidification, drying and dehydration of materials and products in industries such as pharmaceuticals, chemicals, food, agricultural and sideline products, aquatic products, light industry, heavy industry, etc. Such as raw materials, raw medicines, traditional Chinese medicine decoction pieces, extracts, powders, granules, granules, granules, water pills, packaging bottles, pigments and dyes, dehydrated vegetables, dried fruits and vegetables, sausages, plastic resins, electrical components, baking paints, etc.

Description: Heating sources include steam, electricity, far-infrared, and gas and electricity for users to choose from

Category: Non standard oven

Detailed explanation:

Explanation:

1. Heating sources include steam, electricity, far-infrared, and gas and electricity for users to choose from

2. Usage temperature: Steam heating at 50-130 ℃, up to 140 ℃

3. Electricity consumption, far-infrared temperature of 50-300 ℃, can be matched with automatic control system or computer control system, for users to choose from

4. Common steam pressure 0.2-0.8 MPa (2-8 kg/cm2)

5. Equipped with electric heating, calculated as 15kw according to Type 1, practical 5-8kw/h

6. Special requirements should be indicated during ordering

7. Price negotiation for non-standard ovens

8. If the operating temperature is greater than 140 ℃ or less than 60 ℃, it should be noted when placing an order

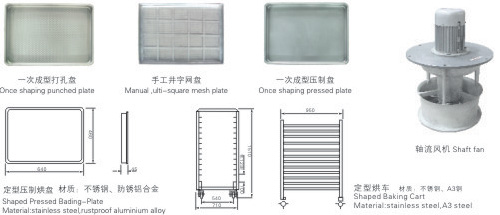

9. Our factory's baking trucks have uniform baking tray sizes and can be interchanged

10. Oven size: 460X640X45mm

Overview:

The CT-C series hot air circulation oven is equipped with a low-noise and high-temperature resistant axial flow fan and an automatic temperature control system. The entire circulation system is fully enclosed, which increases the thermal efficiency of the oven from traditional drying rooms of 3-7% to the current 35-45%, and the thermal efficiency can reach 50%. The successful design of CT-C type hot air circulation oven has enabled China's hot air circulation oven to reach the level of domestic and international standards. It has saved a lot of energy for our country and improved the economic efficiency of enterprises. In 1990, the Medical Administration issued an industry standard with the unified model RXH.

Application: Suitable for heating, solidification, drying and dehydration of materials and products in industries such as pharmaceuticals, chemicals, food, agricultural and sideline products, aquatic products, light industry, heavy industry, etc. Such as raw materials, raw medicines, traditional Chinese medicine decoction pieces, extracts, powders, granules, granules, granules, water pills, packaging bottles, pigments and dyes, dehydrated vegetables, dried fruits and vegetables, sausages, plastic resins, electrical components, baking paints, etc.

Features:

Most of the hot air circulates inside the box, with high thermal efficiency and energy savings. By utilizing forced ventilation, there is an adjustable air distribution plate inside the box, which ensures even drying of materials. The heat source can be steam, hot water, electricity, and far-infrared, with a wide range of options. The whole machine has low noise and balanced operation. Temperature control, easy installation and maintenance. It has a wide range of applications and can dry various materials, making it a universal drying equipment.

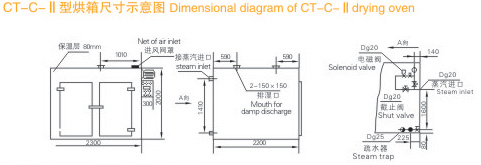

Technical parameter table:

Industry standard models | Model | Each drying amount | Power allocation | Steam consumption | Heat dissipation area | Air volume | Temperature difference between upper and lower parts | Equipped with baking tray | External dimensions | Supporting drying truck |

RXH-5-C | CT-C-0 | 25 | 5 | 5 | 5 | 3400 | ±2 | 8 | 1400×1200×1600 | 0 |

RXH-14-C | CT-C-ⅠA | 50 | 0.45 | 10 | 10 | 3400 | ±2 | 24 | 1400×1200×2000 | 1 |

RXH-14-C | CT-C-I | 100 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2300×1200×2000 | 2 |

RXH-27-C | CT-C-II | 200 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 2300×2200×2000 | 4 |

RXH-41-C | CT-C-III | 300 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 2300×3220×2000 | 6 |

RXH-54-C | CT-C-IV | 400 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 4450×2200×2000 | 8 |

RXH-25-A | High temperature far-infrared oven power matching is carried out according to temperature requirements | 1200×1000×1600 | ||||||||

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23