Product Overview:The fuel is burned through a burner to produce high-temperature gas. And with the help of a hot air stove with enhanced heat exchange measures, the heat of the high-temperature gas is transmitted to the heated air. After the heat is dissipated, the temperature of the high-temperature gas decreases to 250 ℃ and is discharged into the atmosphere.

Description: Fuel is burned through a burner to produce high-temperature gas. And with the help of a hot air stove with enhanced heat exchange measures

Description: Fuel is burned through a burner to produce high-temperature gas. And with the help of a hot air stove with enhanced heat exchange measures

Category: Heat source equipment series

Principle:

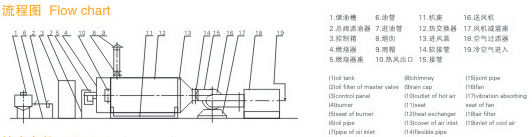

The fuel is burned through a burner to produce high-temperature gas. And with the help of a hot air stove with enhanced heat exchange measures, the heat of the high-temperature gas is transmitted to the heated air. After the heat is dissipated, the temperature of the high-temperature gas decreases to 250 ℃ and is discharged into the atmosphere. The air that needs to be heated is forced into the hot air stove through the optional blower. After absorbing heat, the temperature rises to the rated value and is sent out from the hot air outlet. When the hot air temperature reaches the upper limit of the rated temperature, the burner will automatically stop burning or switch to small flame combustion. When the hot air temperature drops to the lower limit of the rated temperature, the burner will reignite or switch to high flame combustion. The heating speed can be adjusted by adjusting the opening of the inlet valve.

Features:

Widely used in various industrial fields such as pharmaceuticals, chemicals, food, textile printing and dyeing, grain processing, wood processing, automobiles, etc., for drying, curing, heat setting and other operations of various products.

Technical parameters:

Model/Parameters | Output heat(KJ/h) | Output air volume(m3/h) | Output temperature(℃) | Fuel consumption (kg/h) | Burner model |

RLY-2.5 | 1.045×105 | 1500-560 | 60-200 | 4-5 | M4 |

RLY-4 | 1.672×105 | 3500-930 | 60-200 | 6-7 | M8 |

RLY-8 | 3.344×105 | 5600-1480 | 60-200 | 11.5-13.5 | M12 |

RLY-15 | 6.270×105 | 12000-2160 | 60-250 | 21.5-25 | M20 |

RLY-30 | 12.54×105 | 25000-4330 | 60-250 | 43-50 | MP3B |

RLY-40 | 16.72×105 | 28000-5600 | 60-250 | 57-67 | MP4B |

RLY-60 | 25.08×105 | 45000-8660 | 60-250 | 86-100 | MP80AB |

RLYL-80 | 33.44×105 | 83000-12500 | 60-350 | 114-135 | MP130AB |

RLY-160 | 66.88×105 | 134400-23000 | 60-350 | 228-270 | MP200AB |

RLY-200 | 83.60×105 | 170000-28000 | 60-350 | 286-334 | MP300AB |

Note:

1. The output temperature refers to the temperature rise at the input temperature of 20 ℃

2. The combustion value of oil is calculated at 4800KJ/kg.

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23