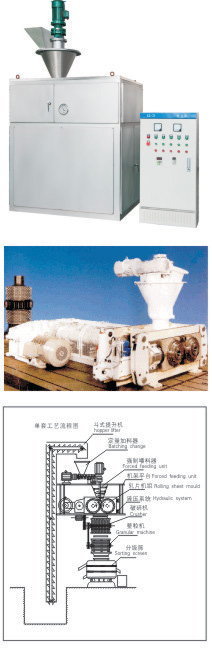

Product Overview:The GFZL series dry powder granulator is a new type of granulation equipment carefully developed by our company based on the absorption of foreign powder granulation technology according to user needs. This equipment can directly produce granular products that meet user requirements from powder raw materials without adding any intermediates or additives. The granulated products have uniform particle size, significantly increased packing density, and can effectively control pollution and reduce powder waste. Scientific design, compact structure, simple process, and convenient operation make it the ideal choice for granulating your powder products.

Description: The GFZL series dry powder granulator is designed by our company to absorb foreign powder granulation according to user needs

Description: The GFZL series dry powder granulator is designed by our company to absorb foreign powder granulation according to user needs

Category: Pellet coating dryer

Detailed explanation:

Overview:

The GFZL series dry powder granulator is a new type of granulation equipment carefully developed by our company based on the absorption of foreign powder granulation technology according to user needs. This equipment can directly produce granular products that meet user requirements from powder raw materials without adding any intermediates or additives. The granulated products have uniform particle size, significantly increased packing density, and can effectively control pollution and reduce powder waste. Scientific design, compact structure, simple process, and convenient operation make it the ideal choice for granulating your powder products.

Working principle:

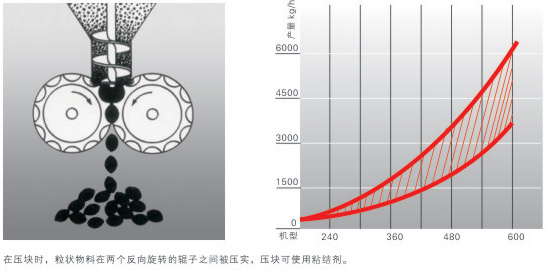

The powdered material is quantitatively fed by a vibrating feeder through a transverse spiral feeder, and uniformly fed into the main material hopper of the rolling mill to maintain a constant amount of material particles. Then, the powder is pre compressed by the longitudinal conical spiral inside the main material hopper of the rolling mill and transported to the arc-shaped groove of the two pressure rollers. The surfaces of the two pressure rollers are evenly distributed with semi flat circular arc grooves or diamond grooves of the same shape. Through a pair of gears, the two pressure rollers rotate in the opposite direction at the same speed. The material conveyed by the conical spiral to the groove is bitten into the groove and instantly forced to compress. After compression, the material gradually decreases with the pressure and falls off from the groove under the action of its elasticity and gravity, entering the crushing whole particle. The system then screens and grades according to the user's particle size requirements to obtain uniformly granular products that meet quality requirements. The screened powder is then returned to the vibrating hopper for recycling.

Features:

● Without any additives, dry powder can be directly granulated

● The particle strength can be adjusted by adjusting the pressure of the pressure roller to control the strength of the finished product

● Loop operation to achieve continuous production

● High finished product output, with a single machine output of over 2000kg/h (stacking density of 1.5 × 103kg/m3)

Application:

Petrochemical, bioengineering, metal powder, fine chemicals, pharmaceuticals, food, pesticides, fertilizers, minerals, coal

Technical parameter table

Model/Project | GFZL-1 | GFZL-2 | GFZL-3 | GFZL-4 | GFZL-5 |

Roll diameter (mm) | φ240 | φ240 | φ300 | φ360 | φ480 |

Effective width of roller usage (mm) | 80 | 160 | 250 | 360 | 480 |

Roll speed (rpm) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

Forming pressure (t) | 50 | 60 | 80 | 100 | 130 |

Roll thickness (mm) | 4 | 5 | 6 | 8 | 8 |

Rolling yield (kg/h) | 250-500 | 500-900 | 700-2000 | 1000-1400 | 2000-7400 |

Finished product particle size (mm) | 0.2-5 | 0.2-5 | 0.2-8 | 0.2-8 | 0.2-8 |

Finished product output (kg/h) | 80-150 | 150-300 | 300-600 | 600-1000 | 1000-2000 |

Host power (kw) | 7.5 | 11 | 15 | 22 | 30 |

Total power (kw) | 13 | 21 | 30 | 46 | 60 |

External dimensions: length x width x height (mm) | 1500×2000×3800 | 1700×2000×4000 | 2000×2500×4200 | 2500×2500×5200 | 2800×2600×6000 |

Weight (t) | 7 | 8 | 10 | 14 | 20 |

Note: 1. The rolling yield is calculated based on the material density of 1500kg/m3and the rolling roller speed of 20rpm. | |||||

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23