Overview:The GSL high-speed mixing granulator is an efficiency equipment that mixes different powdered materials in one process and makes particles, widely used in industries such as pharmaceuticals, food, and chemical industry.

Category: Pellet coating dryer

Category: Pellet coating dryer

Detailed explanation:

Overview:

The GSL high-speed mixing granulator is an efficiency equipment that mixes different powdered materials in one process and makes particles, widely used in industries such as pharmaceuticals, food, and chemical industry.

Features:

● This machine adopts a horizontal cylindrical or conical structure, and users can freely choose.

● The internal surface of the equipment has no dead corners and operates in a closed state, meeting GMP requirements.

● Short granulation time, environmentally friendly and energy-saving.

● The resulting particles have a uniform texture and good fluidity, providing ideal granular raw materials for the tablet pressing process.

● Compared to traditional processes, it reduces adhesive by 25% and shortens drying time.

● Each batch is only dry mixed for 2 minutes and granulated for 1-4 minutes, which improves the efficiency by 4-5 times compared to traditional processes.

● The entire operation has strict safety protection measures.

● When there is a significant difference between the main medicine and excipients, uniform combination can still be achieved without layering.

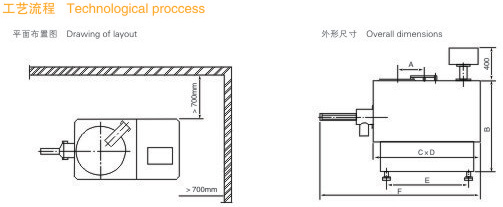

Technical parameter table

Model | A | B | C×D | E | F |

10 | 270 | 750 | 1000×650 | 745 | 1350 |

50 | 320 | 950 | 1250×800 | 970 | 1650 |

150 | 420 | 1000 | 1350×800 | 1050 | 1750 |

200 | 500 | 1100 | 1650×940 | 1450 | 2050 |

250 | 500 | 1160 | 1650×940 | 1400 | 2260 |

300 | 550 | 1200 | 1700×1000 | 1400 | 2310 |

400 | 670 | 1300 | 1860×1100 | 1550 | 2410 |

600 | 750 | 1500 | 2000×1230 | 1750 | 2610 |

Name/Specification | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

Volume(L) | 10 | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

Yield(kg/batch) | 3 | 15 | 50 | 80 | 100 | 130 | 200 | 280 |

Mixing speed(r.p.m) | 300/600 | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 | 80/120 |

Mixed power(kw) | 1.5/2.2 | 4/5.5 | 6.5/8 | 9/11 | 9/11 | 13/16 | 18.5/22 | 22/30 |

Cutting speed(r.p.m) | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 |

Cutting power(kw) | 0.85/1.1 | 1.3/1.8 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 | 9/11 |

Compressed air consumption(m3/min) | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.1 | 1.5 | 1.8 |

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23