Product Overview:In a rotating fluidized bed, the mother batch is subjected to air buoyancy in the annular space, centrifugal force, and self gravity, forming a rope like structure around the ring. Adhesive or coating liquid is sprayed into the material layer to form highly spherical pellets or a continuous and uniform coating film.

Description: Powder or mother batch in a rotating fluidized bed is subjected to air buoyancy in the annular space, centrifugal force, and self gravity

Category: Pellet coating dryer

Detailed explanation:

Overview:

Powder or masterbatch in a rotating fluidized bed is subjected to air buoyancy in the annular space, centrifugal force, and self gravity, forming a rope like structure around the ring. Adhesive or coating liquid is sprayed into the material layer to form highly spherical pellets or a continuous and uniform coating film.

Features:

● Integrating mixing, pelletizing, granulation, and drying, reducing process steps and pollution, and reducing labor intensity.

● The internal and external surfaces of the equipment are smooth and free of dead corners, making it easy to clean and meeting GMP requirements.

Technical parameter table

Project/Specification | 1.5 | 10 | 20 | 30 | 60 | 120 | |

Working volume | L | 5 | 30 | 60 | 105 | 180 | 420 |

Feed quantity | kg/batch | 0.5-1.5 | 3-10 | 8-20 | 10-30 | 20-60 | 40-120 |

Rotating power | KW | 0.55 | 1.5 | 4 | 5.5 | 7.5 | 11 |

Fan power | KW | 4 | 5.5 | 7.5 | 15 | 18.5 | 22 |

Steam consumption | kg/h | 35 | 42 | 84 | 166 | 250 | 332 |

Compressed air | m3/min | 0.3 | 0.6 | 0.6 | 1.1 | 1.8 | 2.4 |

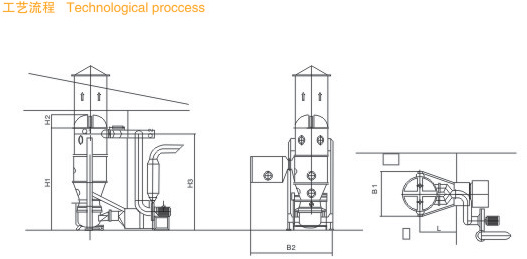

Host size | H1(mm) | 2600 | 2250 | 2850 | 2850 | 3300 | 3500 |

H2(mm) | 320 | 490 | 590 | 690 | 790 | ||

H3(mm) | 2050 | 2600 | 2600 | 3080 | 3280 | ||

φ1(mm) | 400 | 700 | 1000 | 1200 | 1400 | 1600 | |

φ2(mm) | 180 | 180 | 280 | 280 | 280 | 315 | |

B1(mm) | 1650 | 1160 | 1460 | 1660 | 1860 | 2060 | |

B2(mm) | 1800 | 2460 | 2860 | 3260 | 3660 | ||

L(mm) | 1000 | 1250 | 1530 | 1650 | 1650 | 1750 | |

All data is for reference only, and our company has the right to make changes based on the material situation without prior notice. | |||||||

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23