Product Overview:This machine is a continuous flow drying equipment used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for dehydrated vegetables, traditional Chinese medicine slices, and other materials with high moisture content and temperature not allowed to be high; This series of dryers has the advantages of fast drying speed, high evaporation intensity, and good product quality. For paste like materials in the form of dehydrated filter cakes, they can also be dried after granulation or rod-shaped production.

Description: This machine is a continuous flow drying equipment used for drying sheet, strip, and granular materials with good breathability

Category: Belt dryer

Detailed explanation:

Overview:

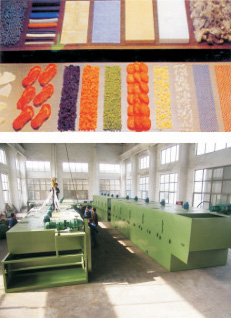

This machine is a continuous flow drying equipment used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for dehydrated vegetables, traditional Chinese medicine slices, and other materials with high moisture content and temperature not allowed to be high; This series of dryers has the advantages of fast drying speed, high evaporation intensity, and good product quality. For paste like materials in the form of dehydrated filter cakes, they can also be dried after granulation or rod-shaped production.

Features:

Features:

● It is possible to adjust the air volume, heating temperature, material residence time, and feeding speed to achieve good drying results.

● The equipment configuration is flexible and can use mesh belt flushing system and material cooling system.

● Most of the air is recycled, highly energy-efficient.

● The unique air distribution device ensures a more even distribution of hot air and consistency in product quality.

● The heat source can be steam, thermal oil, electric or coal-fired (oil) hot air stove matching

Principle:

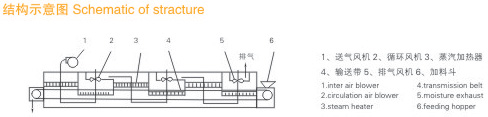

The materials are evenly laid on the mesh belt by the feeder, and the mesh belt is generally made of 12-60 mesh stainless steel wire mesh, which is dragged by the transmission device to move inside the dryer. The dryer consists of several units, each with independent circulation of hot air. Part of the exhaust gas is discharged by a dedicated dehumidification fan, and the exhaust gas is controlled by a regulating valve. The hot air passes through the mesh belt covered with materials from bottom to top or from top to bottom to complete the process of heat and mass transfer, taking away the moisture of the materials. The mesh belt moves slowly, and the operating speed can be freely adjusted according to the material temperature. The dried finished product continuously falls into the receiver. The upper and lower loop units can be flexibly equipped according to user needs, and the number of units can also be selected according to needs.

Application:

Dehydrated vegetables, pellet feed, monosodium glutamate, coconut, organic plastics, synthetic rubber, acrylic fiber, pharmaceuticals, medicinal herbs, small wood products, plastic products, aging and solidification of electronic components, etc.

Model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-12 |

Number of units | 4 | 5 | 4 | 5 | 4 | 6 |

Bandwidth (m) | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 |

Drying section length (m) | 8 | 10 | 8 | 12 | 8 | 12 |

Paving thickness (mm) | 10~80 | |||||

Operating temperature ℃ | 60~130 | |||||

Steam pressure (Mpa) | 0.2~0.8 | |||||

Steam consumption (kgsteam/kgH2O) | 2.2~2.5 | |||||

Drying strength (kgH2O/h) | 6~20kg/m2.h | |||||

Total power of the fan (KW) | 3.3 | 4.4 | 6.6 | 8.8 | 12 | 16 |

Total power of equipment (KW) | 4.05 | 5.15 | 7.35 | 9.55 | 13.1 | 17.1 |

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail.

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23