Product Overview:DWT dehydration dryer is a specialized equipment developed on the basis of traditional mesh belt dryer. It has strong pertinence, practicality, high energy efficiency, and is widely used for dehydration and drying of various regional and seasonal vegetables and fruits, such as garlic slices, pumpkin, konjac, white radish, yam, bamboo shoots, etc.

Description: DWT dehydration dryer is a specialized equipment developed on the basis of traditional mesh belt dryer

Description: DWT dehydration dryer is a specialized equipment developed on the basis of traditional mesh belt dryer

Category: Belt dryer

Detailed explanation:

Overview:

DWT dehydration dryer is a specialized equipment developed on the basis of traditional mesh belt dryer, with strong pertinence, practicality, and high energy efficiency. It is widely used for dehydration and drying of various regional and seasonal vegetables and fruits, such as garlic slices, pumpkin, konjac, white radish, yam, bamboo shoots, etc. It has more than 50 users and more than 80 sets of online equipment. It is an experienced vegetable drying equipment production enterprise in China. Factory technicians have been tracking and serving these users for a long time, conducting in-depth debugging and research, obtaining first-hand practical information, and combining foreign technology to continuously improve and improve the equipment. So far, the third generation DWT series vegetable dehydration dryer has been developed. When producing and manufacturing equipment for users, we take into account the characteristics of the desired drying products and the user's process requirements, Based on the experience accumulated over the past decade, we have designed and produced suitable and high-quality vegetable drying equipment for our users.

Application:

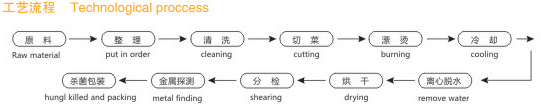

It can meet the drying and large-scale continuous production of vegetable materials such as roots, stems, leaves, strips, blocks, flakes, and large particles, while retaining the nutritional components and colors of the products.

Typical dry ingredients include garlic slices, pumpkin, carrots, konjac, yam, bamboo shoots, horseradish, onions, apples, etc.

Features:

The drying area, wind pressure, air volume, drying temperature, and mesh speed can all be adjusted to meet the characteristics and quality requirements of vegetables.

Different process water processes and necessary auxiliary equipment can be added according to the different characteristics of vegetables.

Principle:

The vegetable dehydration and drying machine consists of main components such as a feeder, drying bed, heat exchanger, and dehumidification fan.

During the operation of the dryer, cold air is heated through a heat exchanger, and a scientific and reasonable circulation method is adopted to allow the hot air to flow through the dry materials on the bed surface for uniform heat and mass exchange. The hot air flow in each unit of the machine is circulated by the circulation fan, and then low-temperature and high humidity air is discharged to smoothly complete the entire drying process.

Technical parameter table:

Model | DWT1.6-Ⅰ | DWT1.6-Ⅱ | DWT1.6-Ⅲ | DWT2-Ⅰ | DWT2-Ⅱ | DWT2-Ⅲ |

Network bandwidth (m) | 1.6 | 1.6 | 1.6 | 2 | 2 | 2 |

Drying section length (m) | 10 | 10 | 8 | 10 | 10 | 8 |

Paving thickness (mm) | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 |

Operating temperature ℃ | 50-150℃ | 50-150℃ | 50-150℃ | 50-150℃ | 50-150℃ | 50-150℃ |

Heat exchange area (m2) | 525 | 398 | 262.5 | 656 | 497 | 327.5 |

Steam pressure (Mpa) | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 |

Drying time (h) | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 |

Installed power (KW) | 15.75 | 12.75 | 9.55 | 20.75 | 16.75 | 12.55 |

External dimensions (m) | 12×1.81×1.9 | 12×1.81×1.9 | 10×1.81×1.9 | 12×2.4×1.92 | 12×2.4×1.92 | 10×2.4×1.92 |

Note:

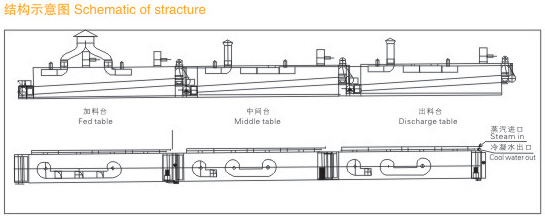

1. Connect the feeding platform, middle platform, and discharge platform of the mesh belt dryer with the unified specifications in the table above to ensure the production process requirements of vegetable dehydration and drying, significantly increase yield, and effectively ensure product quality.

2. The equipment height does not include the height of fans and ducts.

3. Some parameters may be adjusted according to different materials during design, and the design shall prevail

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23