Product Overview:The SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technologies, The SZG double cone vacuum has a two-stage elastic connection method of belt and chain, so the equipment runs smoothly.

Description: The SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technologies

Category: Vacuum dryer

Detailed explanation:

Overview:

Overview:

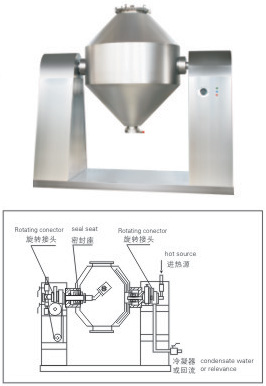

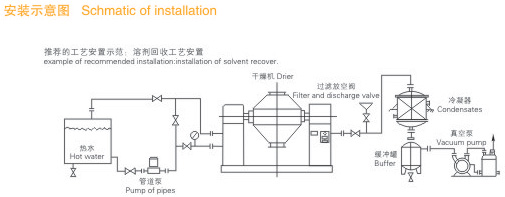

The SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technologies, The SZG double cone vacuum has a two-stage elastic connection method of belt and chain, so the equipment runs smoothly. The specially designed tooling fully reflects the good concentricity of the two shafts, and the heating medium and vacuum system both use reliable American technology rotary joints. On this basis, we developed SZG-A, which can achieve both stepless speed regulation and constant temperature control. As a professional drying equipment manufacturer, we serve our customers with over a hundred units annually. Our products range from high-temperature heat transfer oil as the thermal medium, medium temperature steam, and low-temperature hot water. When drying sticky materials, our factory will specially design a "copying plate" mechanism or set up rolling balls in the tank for you.

Principle:

● Heat energy (such as hot water, low pressure, steam, or thermal oil) is introduced into a closed interlayer, and heat is transferred to the dry material through the inner shell.

● Under power drive, the tank rotates slowly and the materials inside the tank continuously mix, thereby achieving the goal of strengthening drying.

● The material is in a vacuum state, and the decrease in vapor pressure causes the surface moisture (solvent) of the material to reach saturation and evaporate, which is promptly discharged and recovered by a vacuum pump. The water (solvent) inside the material continuously permeates, evaporates, and is discharged from the surface, and the three processes are carried out continuously, achieving the drying goal of the material in a short period of time.

Features:

● When heating oil, automatic constant temperature control is used to dry biochemical products and mineral raw materials, with a temperature range of 20-160 ℃.

● High thermal efficiency, more than twice that of a typical oven.

● Indirect heating ensures that the material is not contaminated and meets "GMP" Requirements. The equipment maintenance operation is simple and easy to clean.

Application:

Suitable for the concentration, mixing, drying, and low-temperature drying of powdered, granular, and fibrous materials in industries such as chemical, pharmaceutical, and food, as well as materials that require low-temperature drying (such as biochemical products). It is more suitable for drying materials that are prone to oxidation, volatilization, heat sensitivity, strong irritation, toxicity, and materials that do not allow crystal damage.

Technical parameter table

Project | Unit | Model | ||||||||||

Name | Unit | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

Total volume | L | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

Working volume | L | 50 | 100 | 175 | 250 | 375 | 500 | 750 | 1000 | 1500 | 2000 | 2500 |

Heating area | m2 | 1.16 | 1.5 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 10.2 | 12.1 | 14.1 |

Speed | Rpm | 6 | 5 | 4 | 4 | 4 | ||||||

Power | Kw | 0.75 | 1.1 | 1.5 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 7.5 |

Rotating height | mm | 1810 | 1910 | 2090 | 2195 | 2500 | 2665 | 2915 | 3055 | 3530 | 3800 | 4180 |

Overall weight | kg | 825 | 1050 | 1350 | 1650 | 1800 | 2070 | 2250 | 3000 | 4500 | 5350 | 6000 |

Design pressure inside the tank | Mpa | -0.09~0.096 | ||||||||||

Sandwich design pressure | Mpa | 0.3 | ||||||||||

| The motor can be equipped with a variable speed motor according to user requirements, with a speed range of 0-6rpm The capacity of this machine can be designed to be 10000L | ||||||||||||

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23