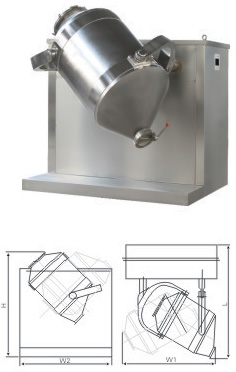

Product Overview:SYH multi-directional motion mixer is widely used in pharmaceutical, chemical, food, metallurgy, light industry, and scientific research institutions. It can evenly mix powder or granular materials with good fluidity, so that the mixed materials can achieve a good mixing state.

Synopsis: SYH multi-directional motion mixer is widely used in pharmaceuticals, chemicals, food, metallurgy

Synopsis: SYH multi-directional motion mixer is widely used in pharmaceuticals, chemicals, food, metallurgy

Category: Hybrid equipment series

Detailed explanation:

Application:

SYH multi-directional motion mixer is widely used in pharmaceutical, chemical, food, metallurgy, light industry, and scientific research institutions. It can evenly mix powder or granular materials with good fluidity, so that the mixed materials can achieve a good mixing state.

Features:

Due to the multi-directional movement of the mixing barrel, there are multiple cross mixing points for the materials inside the barrel, resulting in high mixing efficiency and a uniformity of over 99.9%. The loading coefficient can reach 0.9 (0.4-0.6 for ordinary mixers), short mixing time, and high efficiency

The mixing barrel of this machine has a unique design, with the inner wall of the barrel finely polished, no dead corners, no material pollution, convenient discharge, easy cleaning, and simple operation.

Working principle:

During operation, due to the multi-directional operation of the mixing barrel, various materials accelerate their flow and diffusion during the mixing process, while avoiding the phenomenon of material density segregation and accumulation caused by centrifugal force in general mixers. The mixing has no dead corners and can effectively ensure the excellent quality of the mixed materials

Structure: The machine consists of a base, transmission system, electrical control system, multi-directional motion mechanism, mixing cylinder and other components. The mixing cylinder in direct contact with the material is made of high-quality stainless steel material, and both the inner and outer walls of the barrel are mirror polished.

Technical parameters:

Model | SYH-5 | SYH-100 | SYH-200 | SYH-400 | SYH-600 | SYH-800 | SYH-1000 | SYH-1500 | |

Mixing bucket volume(L) | 5 | 100 | 200 | 400 | 600 | 800 | 1000 | 1500 | |

Loading capacity(L) | 4 | 80 | 150 | 300 | 450 | 600 | 750 | 1200 | |

Loading weight(kg) | 5 | 80 | 150 | 200 | 300 | 400 | 500 | 750 | |

Spindle speed(r/min) | 24 | 15 | 12 | 10 | 10 | 10 | 10 | 10 | |

Motor power(kw) | 0.37 | 1.5 | 3 | 4 | 5.5 | 7.2 | 11 | 11 | |

External dimensions(mm) | L | 600 | 1200 | 1300 | 1500 | 1800 | 1900 | 1950 | 2600 |

W | 1000 | 1800 | 1600 | 2200 | 2500 | 2400 | 2500 | 2500 | |

H | 1000 | 1500 | 1500 | 1500 | 1650 | 2100 | 2400 | 2350 | |

Weight(kg) | 150 | 500 | 750 | 1200 | 1500 | 1650 | 1800 | 2500 | |

Changzhou Zhihong Drying Technology Co., Ltd. is located in the economically developed center of the Yangtze River Delta, Zhenglu Town, Changzhou City. It borders Shanghai to the east and Nanjing to the west, and is situated at the intersection of Hengshan on the Shanghai Nanjing Expressway. It is more than ten miles away from Changzhou Airport and train station, and the transportation is very convenient. The company is a designated production enterprise in the pharmaceutical equipment industry, chemical equipment industry, and food machinery drying equipment industry in China. The company has 60 categories and more than 280 specifications of products, with an annual output of 500 sets of drying, granulation, mixing, crushing, concentration, and extraction equipment, and its products meet GMP requirements.

The company's main products include pharmaceutical machinery, chemical machinery, food machinery, pigment drying machinery, and other products. The products have now covered various markets across the country and are highly favored and praised by domestic users.

How to choose a suitable hot air circula···

24.05.24The integration of drying equipment into···

24.05.24Experts analyze that the Chinese rotary ···

24.05.24Comparison and difference between ultraf···

24.05.24Working principle of purification hot ai···

24.05.24Spray drying is a method of systematic t···

24.05.24Methods of spray drying and comparison o···

24.05.24Internal structure and atomization proce···

24.05.24Granulation function of horizontal spray···

24.05.24Energy efficiency and drying temperature···

24.05.23